Edge Device Safety Detection: AI-Powered Workplace Safety Monitoring

Retail Client

At a Glance

Client: Retail Client, Portugal

Industry: Workplace Safety & Surveillance

Challenge: Manual CCTV monitoring that was labor-intensive, inconsistent, and prone to human error

Solution: AI-powered edge computing system for real-time safety violation detection

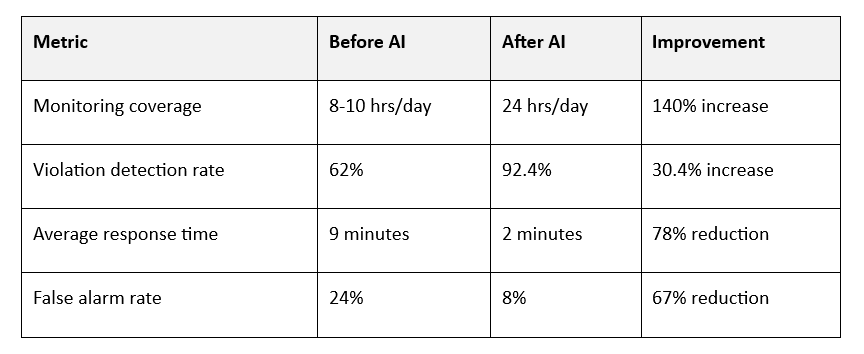

Results: 24/7 monitoring coverage, 92.4% detection accuracy, 78% faster incident response time

“The Edge Device Safety Detection system has transformed our approach to workplace safety monitoring. What was once a tedious manual process is now automated, consistent, and significantly more effective.”

— Retail Client , Manager

The Challenge

Mayvel identified a critical gap in workplace safety monitoring across their clients’ sites. Most industrial facilities were equipped with CCTV cameras, but the monitoring process suffered from significant limitations:

Key Pain Points

- Human Limitations: Manual monitoring was subject to fatigue, distraction, and inconsistent attention

- Coverage Gaps: Impossible to maintain consistent monitoring across multiple cameras 24/7

- Delayed Responses: Critical safety violations often identified too late to prevent incidents

- Subjective Assessment: Lack of standardized criteria for violation detection

- Scaling Difficulties: Adding more human monitors was cost-prohibitive for multi-site operations

These challenges resulted in missed safety violations, increased incident rates, and difficulty enforcing consistent safety standards across operations.

Our Approach

We partnered with Mayvel to develop EdgeDeviceSafetyDetection, an AI-powered system that transforms existing CCTV infrastructure into automated safety monitoring stations. Our implementation followed a strategic four-phase approach:

Phase 1: System Architecture & Planning

1 Week

- Conducted site assessments across 4 client facilities

- Cataloged existing CCTV infrastructure and capabilities

- Identified key safety violations for detection

- Developed edge computing strategy optimized for on-site processing

Phase 2: AI Engine Development

6 Weeks

- Trained a custom deep learning model (YOLOv11 Nano) achieving 92.4% detection accuracy

- Developed specialized detection for PPE compliance (helmets, harnesses, safety vests)

- Created algorithms for hazardous behavior recognition including falls and physical altercations

- Implemented real-time notification system with configurable alert thresholds

- Built evidence capture system with automatic snapshots and timestamps

Phase 3: Integration & Testing

3 Weeks

- Deployed edge computing devices at test sites

- Connected system to existing CCTV cameras

- Conducted comparative testing against manual monitoring

- Refined detection parameters based on real-world performance

Phase 4: Deployment & Optimization

2 Weeks

- Initiated pilot deployment at Chennai manufacturing site

- Established alert workflows and response protocols

- Implemented performance monitoring and telemetry collection

- Created feedback mechanisms for ongoing model refinement

The Technology

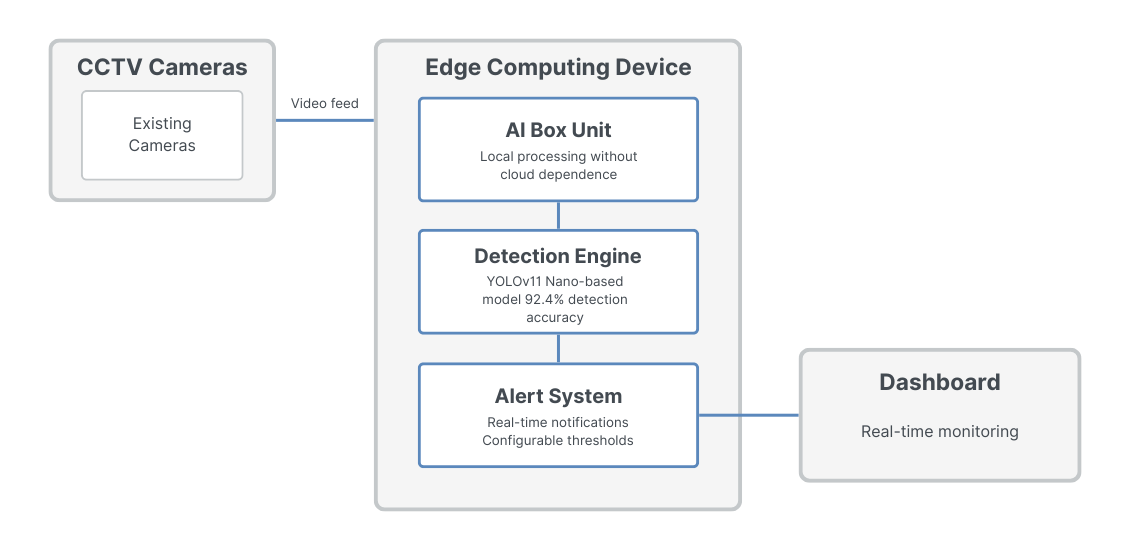

Edge Device Safety Detection uses AI and edge computing for real-time safety monitoring:

The Edge Device Safety Detection hardware combines powerful computing capabilities with a compact form factor, allowing for discreet installation and processing of multiple camera feeds simultaneously.

Key Technical Features

- Custom-Trained Deep Learning: YOLOv11 nano-based model achieving 92.4% accuracy for safety violation detection

- Edge-Based Processing: Local processing without cloud dependence ensures privacy and minimal latency

- Multi-Camera Support: Single edge device can monitor multiple camera feeds simultaneously

- Real-Time Notifications: Immediate alerts when violations are detected with configurable thresholds

- PPE Compliance Detection: Identifies workers without required safety equipment (helmets, vests, harnesses)

- Hazard Behavior Recognition: Detects fighting, restricted zone entry, falls, and medical distress situations

- Evidence Capture: Automatic screenshots with violation highlighting for documentation and training

Business Outcomes

- Enhanced Safety: 46% reduction in reportable safety incidents within six months

- Operational Efficiency: Significant reduction in required manual monitoring hours

- Improved Compliance: Comprehensive digital evidence for regulatory inspections

- Staff Optimization: Reallocation of safety personnel to preventative activities rather than monitoring

“This system catches safety violations that human monitors would easily miss. The immediate alerts have allowed us to address potentially dangerous situations before they escalate into incidents.”

— Site Safety Coordinator, Mayvel Client

Conclusion

The EdgeDeviceSafetyDetection system demonstrates how Mayvel has leveraged advanced AI technology to transform traditional safety monitoring.